CAD (0)

▾

Self-Clinching TY-D®Cable Tie-Mounts - Unified Type TD/TDS

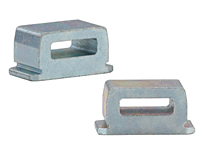

Standard Tie-Mount – Types TD™/TDS™

PEM® TY-D® self-clinching tie-mounts and hooks provide secure attachment points for mounting wires to electronic chassis or enclosures. All TY-D hardware installs quickly and permanently without screws and eliminates the use of adhesives that typically fail over time and temperature cycling.

Type TD™/TDS™ mounts allow users to easily slide ties through the hardware’s “eye” for fast cable mounting. Type TDO™ hooks* enable users to attach, remove, and return tie-bundled wires to their mounting points when components need to be accessed for service or when wires must be replaced. The hook feature allows ties to remain intact and wires to remain wrapped.

TY-D hardware can be a great improvement over traditional mounting methods. They can be placed with assurance at designed locations and angles to remain secure for the life of the assembly; they will not protrude on the reverse side and will not affect the reverse side appearance or clearance; and panels remain flush, minimizing EMI/RFI and contamination of electronics by dust or dirt.

Type TD™/TDS™ mounts allow users to easily slide ties through the hardware’s “eye” for fast cable mounting. Type TDO™ hooks* enable users to attach, remove, and return tie-bundled wires to their mounting points when components need to be accessed for service or when wires must be replaced. The hook feature allows ties to remain intact and wires to remain wrapped.

TY-D hardware can be a great improvement over traditional mounting methods. They can be placed with assurance at designed locations and angles to remain secure for the life of the assembly; they will not protrude on the reverse side and will not affect the reverse side appearance or clearance; and panels remain flush, minimizing EMI/RFI and contamination of electronics by dust or dirt.

Item # |

Profile |

L - Length ± .003 |

Sheet Thickness |

Hole Size In Sheet + .002 -.001 |

E ± .006 |

G - Height ± .006 |

CAD |

|---|---|---|---|---|---|---|---|

| TD-40-4ZI | Profile N/A 40 | L - Length ± .003 N/A .121 in | Sheet Thickness N/A .040 - .050 in | Hole Size In Sheet + .002 -.001 N/A .250 x .125 in | E ± .006 N/A .308 in | G - Height ± .006 N/A .150 in |

CAD

N/A

|

| TD-60-6ZI | Profile N/A 60 | L - Length ± .003 N/A .184 in | Sheet Thickness N/A .040 - .070 in | Hole Size In Sheet + .002 -.001 N/A .312 x .187 in | E ± .006 N/A .370 in | G - Height ± .006 N/A .180 in |

CAD

N/A

|

| TD-175-12ZI | Profile N/A 175 | L - Length ± .003 N/A .371 in | Sheet Thickness N/A .040 - .125 in | Hole Size In Sheet + .002 -.001 N/A .500 x .375 in | E ± .006 N/A .562 in | G - Height ± .006 N/A .285 in |

CAD

N/A

|

| TDS-40-4 | Profile N/A 40 | L - Length ± .003 N/A .121 in | Sheet Thickness N/A .040 - .050 in | Hole Size In Sheet + .002 -.001 N/A .250 x .125 in | E ± .006 N/A .308 in | G - Height ± .006 N/A .150 in |

CAD

N/A

|

| TDS-60-6 | Profile N/A 60 | L - Length ± .003 N/A .184 in | Sheet Thickness N/A .040 - .070 in | Hole Size In Sheet + .002 -.001 N/A .312 x .187 in | E ± .006 N/A .370 in | G - Height ± .006 N/A .180 in |

CAD

N/A

|

| TDS-175-12 | Profile N/A 175 | L - Length ± .003 N/A .371 in | Sheet Thickness N/A .040 - .125 in | Hole Size In Sheet + .002 -.001 N/A .500 x .375 in | E ± .006 N/A .562 in | G - Height ± .006 N/A .285 in |

CAD

N/A

|

| TDS-40-4ZI | Profile N/A 40 | L - Length ± .003 N/A .121 in | Sheet Thickness N/A .040 - .050 in | Hole Size In Sheet + .002 -.001 N/A .250 x .125 in | E ± .006 N/A .308 in | G - Height ± .006 N/A .150 in |

CAD

N/A

|

| TDS-60-6ZI | Profile N/A 60 | L - Length ± .003 N/A .184 in | Sheet Thickness N/A .040 - .070 in | Hole Size In Sheet + .002 -.001 N/A .312 x .187 in | E ± .006 N/A .370 in | G - Height ± .006 N/A .180 in |

CAD

N/A

|

| TDS-175-12ZI | Profile N/A 175 | L - Length ± .003 N/A .371 in | Sheet Thickness N/A .040 - .125 in | Hole Size In Sheet + .002 -.001 N/A .500 x .375 in | E ± .006 N/A .562 in | G - Height ± .006 N/A .285 in |

CAD

N/A

|