Thread Size

|

N/A

.375-16 (3/8-16)

|

Thread Code

|

N/A

0616

|

Length Code

|

N/A

12

|

Material Code

|

N/A

B

|

|

Min. Sheet Thickness1

|

N/A

.090 in

|

Hole Size in Sheet + .005 - .000

|

N/A

.375 in

|

Max. Hole in Attached Parts

|

N/A

.437 in

|

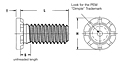

L - Length ± .015

|

N/A

.750 in

|

H ± .01

|

N/A

.580 in

|

|

S Max.2

|

N/A

.155 in

|

T Max.

|

N/A

.085 in

|

Min. Dist. Hole C/L to Edge

|

N/A

.530 in

|

Thread Strength

|

N/A

60 ksi

|

For Use in Sheet Hardness

|

N/A

HRB 55 / HB 83 or Less

|

Thread Specification

|

N/A

External, ANSI B1.1, 2A

|

Fastener Material

|

N/A

CDA-510 Phosphor Bronze

|

Standard Finish

|

N/A

No Finish

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|