Thread Size

|

N/A

.112-40 (#4-40)

|

Thread Type

|

N/A

Self-Locking

|

Thread Code

|

N/A

440

|

Shank Code

|

N/A

1

|

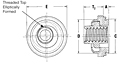

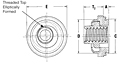

A (Shank) Max.

|

N/A

0.038 in

|

|

Min. Sheet Thickness1

|

N/A

.038 in

|

Hole Size in Sheet + .003 - .000

|

N/A

.290 in

|

C Max.

|

N/A

.289 in

|

D Max.

|

N/A

.290 in

|

E ± .015

|

N/A

.360 in

|

T1 Max.

|

N/A

.130 in

|

T2 Max.

|

N/A

.190 in

|

Min. Dist. Hole C/L to Edge

|

N/A

.300 in

|

Float

|

N/A

.015” minimum, in all directions from center, .030” total

|

Fastener Material

|

N/A

400 Series Stainless Steel

|

Fastener Materials - Retainer

|

N/A

400 Series Stainless Steel

|

Fastener Materials - Nut

|

N/A

300 Series Stainless Steel

|

Retainer Finish

|

N/A

Passivated and/or tested per ASTM A380

|

Nut Finish

|

N/A

Black Dry-film Lubricant

|

|

For Use in Sheet Hardness2

|

N/A

HRB 88 / HB 183 or Less

|

Thread Specification

|

N/A

Internal, ANSI B1.1, 2B

|

CAD Supplier

|

N/A

PennEngineering® (PEM®)

|